PRODUCTION

Production profile

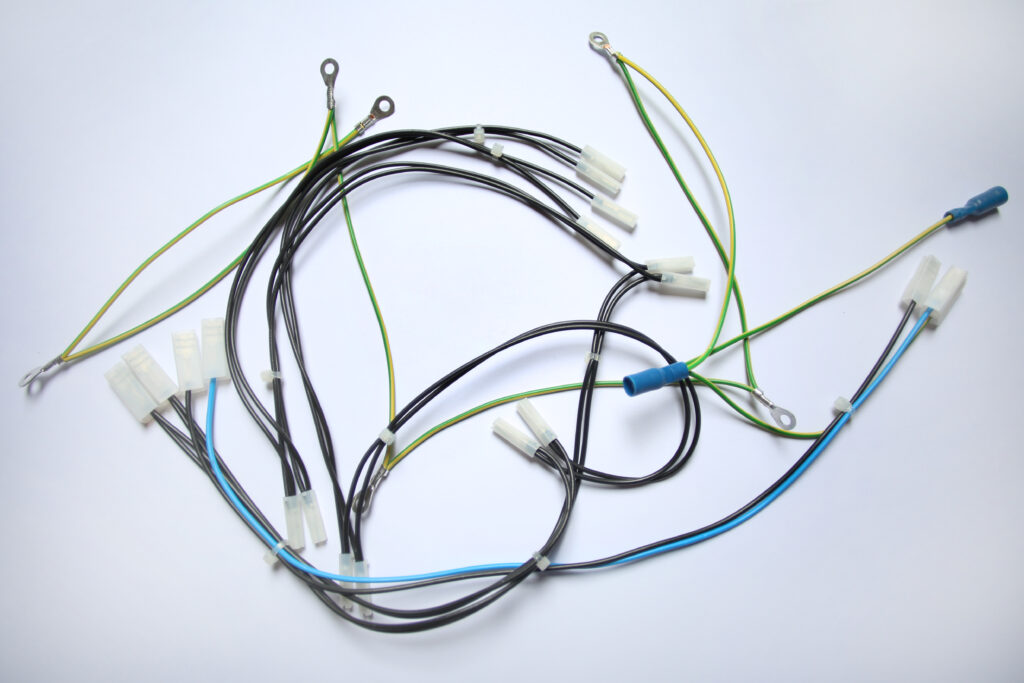

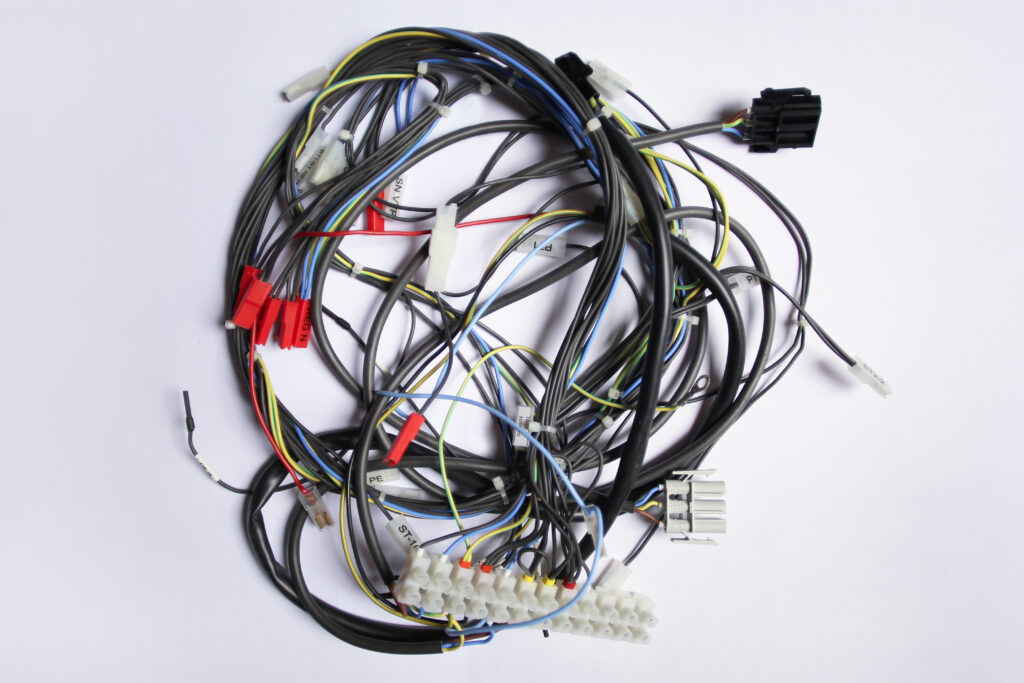

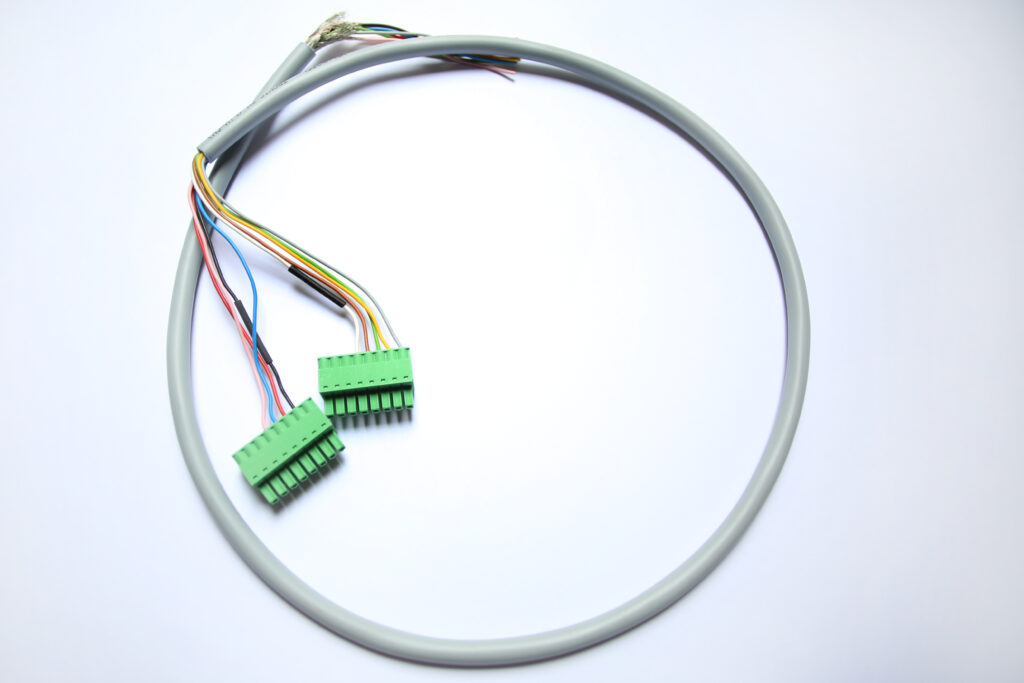

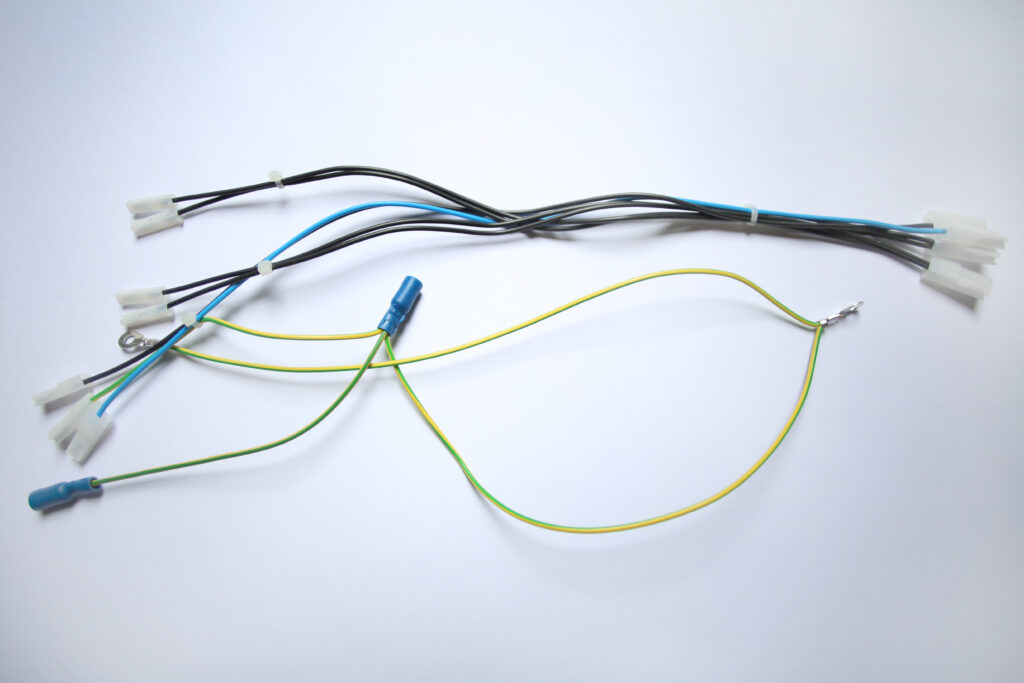

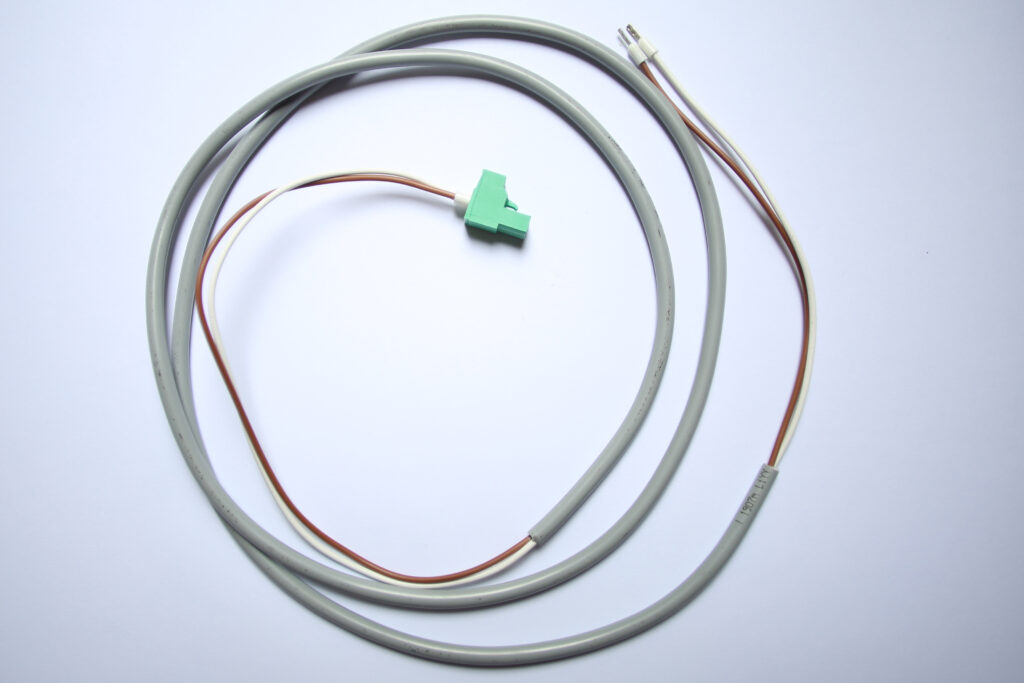

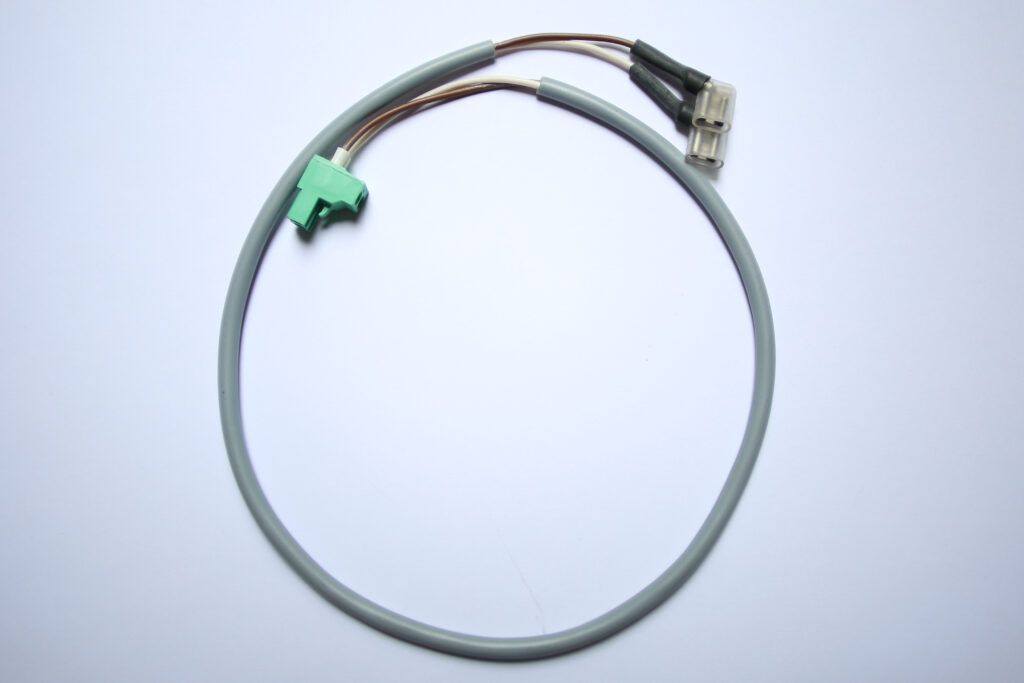

Optimization and production of cable harnesses

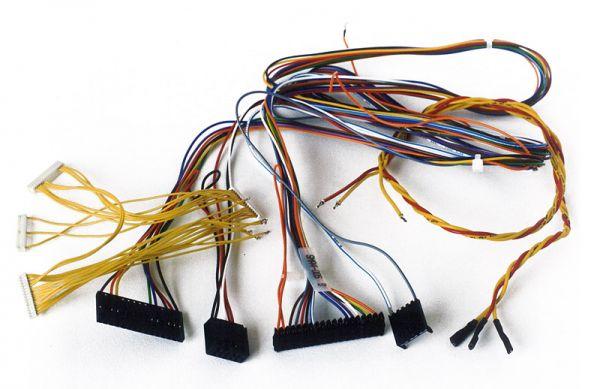

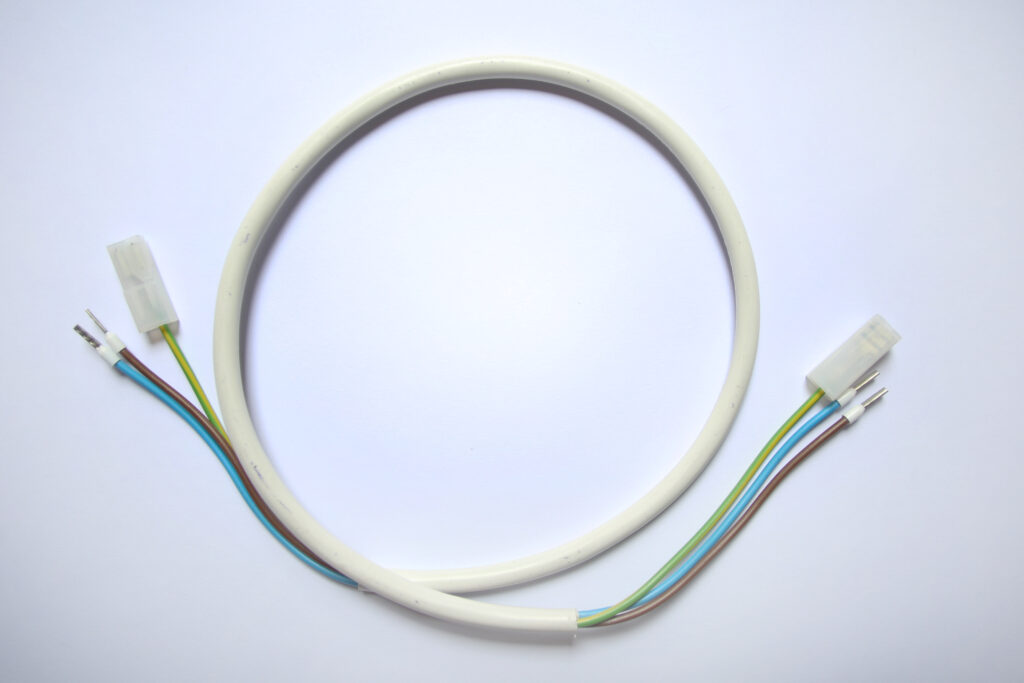

Production of individual wires and complex cable trees combined with electronic and electromechanical components.

The main objective of our company is to meet the customer’s needs in terms of price, product quality and delivery dates to the maximum extent, with a special emphasis on flexibility and customer support.

Production of individual wires and complex cable trees combined with electronic and electromechanical components.

The main objective of our company is to meet the customer’s needs in terms of price, product quality and delivery dates to the maximum extent, with a special emphasis on flexibility and customer support.

Cable harnesses - production

In co-operation with customers we design a cable harness production to meet the requirements of functionality, cost and quality to the maximum extent. We are able to recommend to Customers suitable materials and technologies from reputable companies to achieve the result desired.

The production is subsequently carried out on a basis of approved documents (drawing documentation or reference samples). The products are delivered to domestic and foreign customers. All production is realized according to the requirements of ISO 9001 standards.

The optimal production or assembly technology with respect to the production capacity is designed in the production or assembly planning process already. The production technology used can fundamentally affect the quality of delivered products. The company has a technology for both serial and piece production.

The production processes we offer to our customers

- multicore cables processing (unshielded design)

- implementation of special requirements according to Automotive standards specifications

- automated cutting of single wire conductors including stripping and pressing (crimping).

- stripping of single-core and multi-core cables

- processing of connectors of conventional and self-tapping systems (Molex, Ensto, Stocko, Lumberg, Tyco)

- tinning of wire ends

- automatic and manual pressing of non-insulated and insulated contacts

- point soldering

- unleaded soldering

- stranding and subsequent insulating of cables

- winding and bundling of finished products

- cable ties and banding

- moulding (cable moulding)

- testing of correct connections and harness functions

- output control